We live in a new world today, and COVID has impacted everybody in the print industry. As far as print embellishment was concerned, we saw a unique set of circumstances that negatively impacted some applications.

Surprisingly, we observed an unexpected acceleration in other applications and overall market adoption due to several factors, including COVID.

Digital Embellishments can mean several things, so what is the true definition, and what types of decorating and embellishments are possible through digital processes?

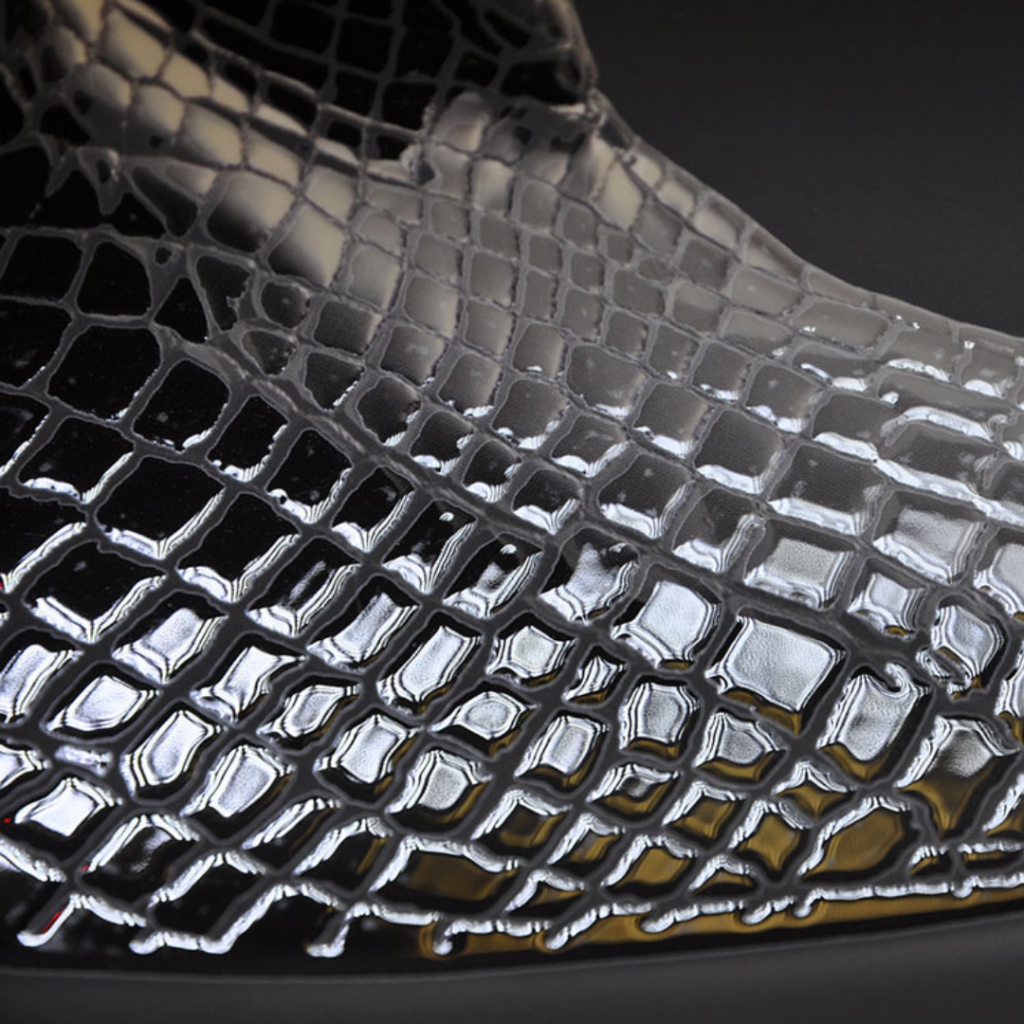

The prevailing definition of digital embellishment is the process by which a physical, visual, or tactile effect is added to a printed piece of matter to enhance it using technology that does not require any tooling, thus allowing for variability in data and significant cost-effectiveness in short runs.

We see many different types of digital embellishment technologies being used, and the utilization of these various techniques depends on the different budgets, desired effects, technical limitations, and environmental considerations of the printers, the brands, and the agencies who require them.

One of the oldest and most well-known types of digital embellishment is “Sleeking,” whereas we remelt black toner from a digital print engine through a laminator. Instead of a roll of laminate, we alternatively load a roll of foil.

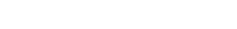

The black toner heats up, melts, and sticks to the foil and whatever you printed in black is now metalized. Many different effects can be reached using this technology, such as metallics, simulated Spot UV, and more. Still, to have this foil part of an overall cmyk+ design requires the use of multiple passes through the digital press, very high registration precision, and barriers such as lamination between steps for it to work.

It should also be said that the overall effect of Sleeking-based output is generally going to be “flat” and not dimensionally raised. While it is not a necessarily efficient process and requires time to produce and print clicks for each pass, it offers a low cost of entry and is perfect for people who want to test the waters of embellishment.

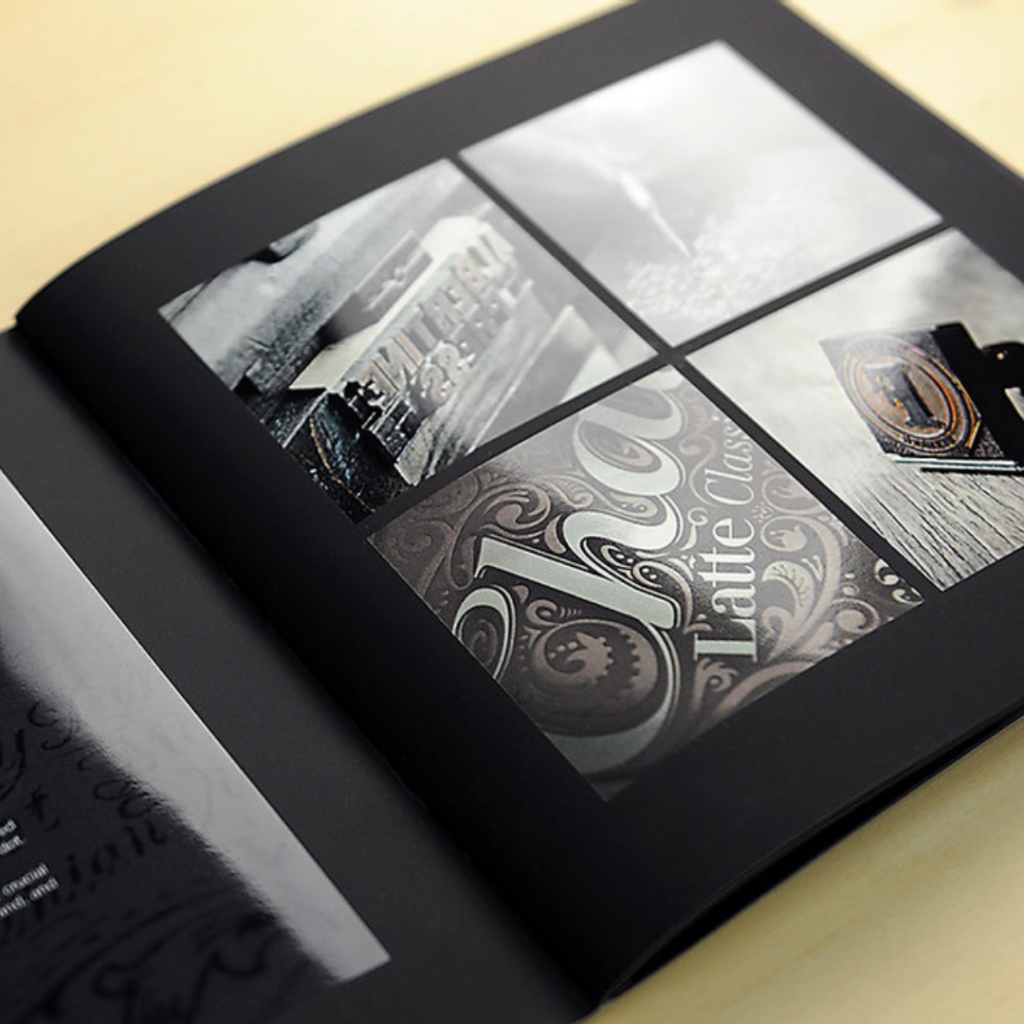

Then, making its entrance a little over a decade ago are the inkjet-based systems. The inkjet-based systems first started by jetting a clear ink onto printed sheets to simulate Spot UV. A few years later, there was the idea that tactile effects could also be achieved by adding more layers or slowing the process down, so tactile embellishment was born. Finally, a few years later, the idea was born that the fluid itself could act as an adhesive agent for foil products by formulating a specific fluid in a very specific way. So the premise was, with one piece of technology, having the ability to do a flat spot UV, a raised clear tactile effect, and a raised foil effect all in one pass with a minimum run of one.

Mass-level democratization had begun thanks to the many new players, new formats, new platforms, and diverse budget levels.

Then we saw the integration of special effects in digital printing presses, which began to flaunt fluorescent colors, metallics, and dimensionality in line with their digital CMYK+ printing processes. This made it easy to produce spectacular prints that could stand out from the regular offerings.

Today, we are witnessing a renaissance in the print enhancement market segment thanks to the democratization of easy-to-use digital embellishment technologies and the understanding that “informational” print is migrating online. In contrast, “impactful” print is the end game in most brands’ print budgets today. What has been especially interesting to watch has been how digital print embellishment has also helped increase volumes on traditional analog embellishment technologies by reigniting interest in these new finishes.